Hand Protection - Getting Back to Basics

Work gloves play a crucial role in protecting workers' hands from potential injuries. To ensure safety and optimize their efficacy, it is imperative to grasp the manufacturing process and the correct utilization of work gloves. You will find a brief about work gloves and their uses. Get a fit and comfortable work gloves now at www.idemcosb.com.my

Manufacturing Process:

|

a. Material Selection: Work gloves are crafted from various materials, including leather, synthetic fibers (such as nylon, polyester, or spandex) and specialized coatings (such as latex or nitrile). The choice of material depends on the intended application and potential hazards workers may encounter. |

|

b. Cutting and Stitching: Selected materials are carefully cut into pattern pieces that align with the glove design. Skilled workers then use specialized sewing machines to stitch these pieces together, ensuring durability and a proper fit. |

|

c. Quality Control: Stringent quality control measures are integrated throughout the manufacturing process to ensure that the gloves adhere to safety standards. These measures include inspections to detect defects, assess sizing accuracy, and test material strength and durability. |

Usage Guidelines:

|

1. Proper Selection: It's crucial to select work gloves that are suitable for the specific task and potential hazards. Considering factors such as chemical resistance, cut resistance, and grip requirements when choosing gloves. |

|

2. Size and Fit: Choose the gloves that is comfortable and fit with your hand, ensuring both security and dexterity. Safety gloves that are too loose or too tight can compromise performance and safety. |

|

3. Inspection: Before using, meticulously examine gloves for any signs of damage, such as tears, holes, or areas showing wear. Avoid using gloves with visible defects because they may not provide adequate protection. |

|

4. Donning and Doffing: Follow correct procedures for putting on and removing gloves to minimize contamination and ensure a secure fit. Avoid touching the outer surface of gloves, especially after handling hazardous substances. |

|

5. Care and Maintenance: Comply with manufacturer recommendations for cleaning and maintaining gloves. This may involve handwashing, machine-washing, or disinfection, depending on the type of glove. Proper maintenance helps extend the gloves' lifespan and preserves their protective properties. |

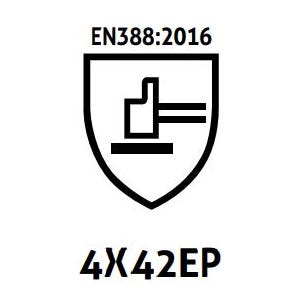

The New EN Ratings

If you've ever wondered about the numbers on your gloves, they represent the scores indicating how well your gloves perform against various hazards. You can identify an EN 388 rated glove by looking for the symbol below on the gloves, packaging or conformity statement.

|

|

Hazard |

Resistance Rating |

|

Abrasion Resistance |

Level 1-4 |

|

Cut Resistance |

Level 1-5 |

|

Tear Resistance |

Level 1-4 |

|

Puncture Resistance |

Level 1-4 |

|

ISO Cut Resistance |

A-F |

|

Impact Resistance |

Passed(P), Failed(F), Not Tested(X) |

Abrasion Resistance (Scale of 1-4)

Each glove's material undergoes pressure testing with sandpaper. In this initial category, safety gloves are rated on a scale of 1-4 based on the number of turns needed for a hole to develop in the material. A higher rating signifies superior abrasion resistance, indicating the glove's ability to withstand wear and tear.

Cut Resistance (Scale of 1-5)

The rating is determined by the number of cycles necessary to cut through the glove at a consistent and constant speed. A higher rating indicates that it took longer for the blade to penetrate the material. In cases where the material dulls the blade, the TDM test (as described below) will be conducted instead.

Tear Resistance (Scale of 1-4)

Each glove is tested by force to see how much is required to create a tear in the material.

A rating of 4 signifies that the gloves are crafted from the strongest material.

Puncture Resistance (Scale of 1-4)

Force is applied to the material to see how much is required for a puncture to occur using a standard size point. The higher number indicate they are more resistant to punctures.

ISO Cut Resistance (Scale of A-F)

The rating is defined by the average load required to cut the material using a straight blade.

Gloves rated ‘F’ showed that they required the greatest force of Newtons to cut through.

However, gloves with rating ‘A’ means the glove have little cut resistance.

Impact Resistance (Scale of P, F, X)

Impact resistance will only show when the glove is indicated by the scale of P, F, X. If the gloves did not include the sixth digit as the symbol shown above, the gloves will not claim to have impact protection.

Safety is the top priority for everyone. By reading this article, you can gain knowledge about safety gloves manufacturing process, gloves usage guidelines and safety gloves key rating about which safety gloves are most suitable for your specific job needs. Idemco has over 20 years of experience in distributing a wide range of reliable safety gloves in Malaysia to meet various job requirements. Optimax tools are designed and manufactured to meet or surpass the stringent standard requirements.

3791

3791